I decided to start 2019 off with a carved box in northern red oak. The overall dimensions of the box will be, 10-1/2″ D x 17-1/2″ W x 9-1/2″ H. Not knowing what pattern to carve, I just established horizontal and vertical centerlines and stared at the board for a spell.

After several minutes with no clue as to what to carve, I began adding an S-braid as a bottom margin, thinking perhaps that would spark an idea. Firstly, I scribed margins as shown.

Then using dividers I walked 5/8″ spaces across the board and used an eye punch to mark off these spaces.

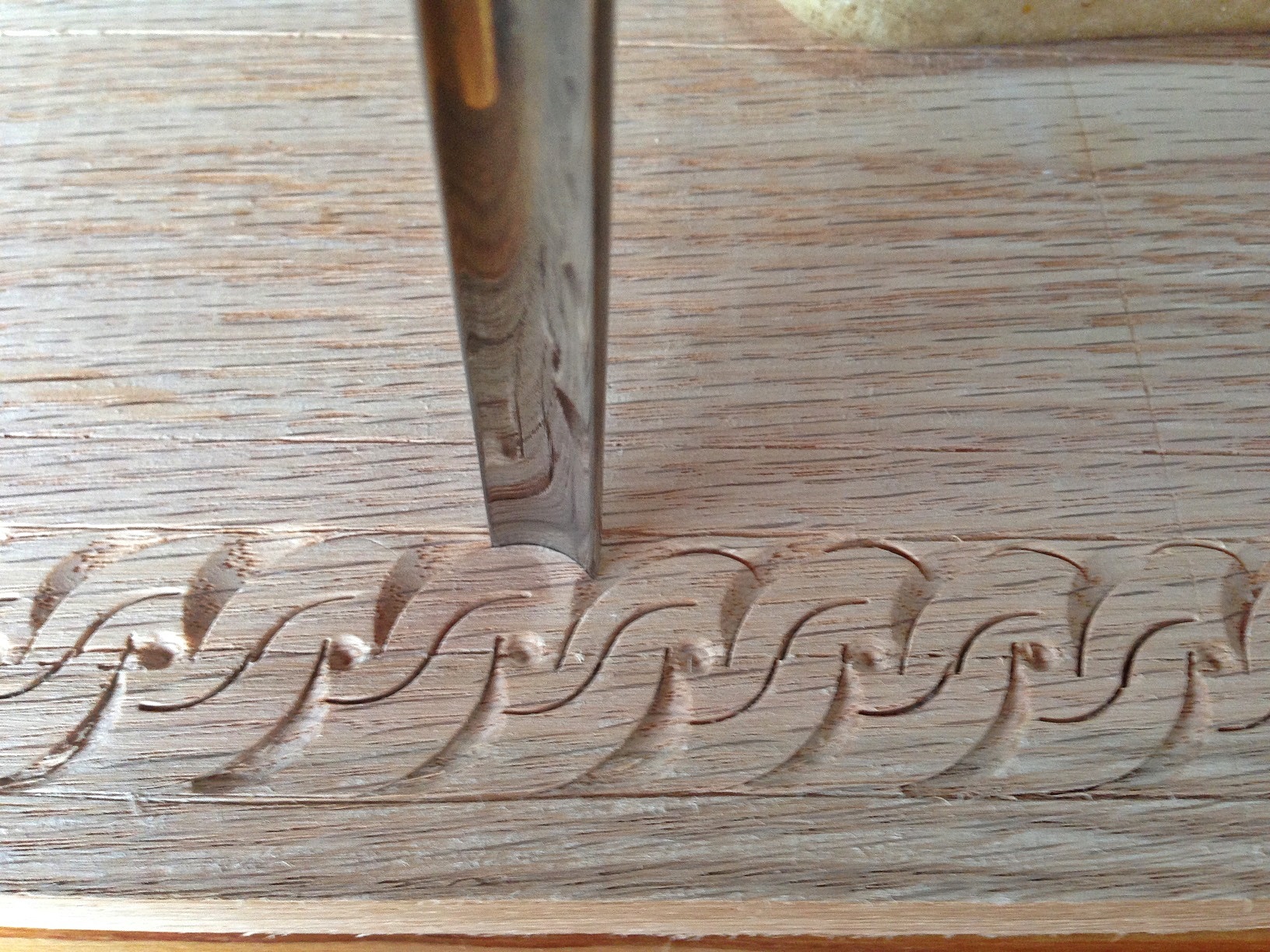

Then using a 20 mm #7 gouge, I made strikes from the center line to the top margin just to the right of the punch marks. Reversing the gouge, I made strikes from the center line to the bottom margin just to the left of the punch marks. Chips were then removed.

From the center line to where the chips were removed, I made strikes with a 10 mm #7 gouge, both top, and bottom.

Using the same 10 mm #7, I rounded over the first 20 mm gouge strikes and removed the chip.

After an hour or so I had an S-braid as a bottom margin!

Still, with no clue as to what the main pattern would be, I decided to add some running cable as a top margin.

So … inverted lunettes, S-scrolls, or rondels … I guess time will tell!

Slow start to the year for me so far. I made mini-challah knots for our neighborhood New Years Day get-together yesterday. Did get some spalted maple and hard maple cut into chunks and mixed up red and blue resin solutions and dried the wood in the aftermath of the bread in the oven. Today I’ll dye the wood, bake the resin dry, and then hit it with black as a secondary color. And hopefully finish making the spline-cutting jig I started on Monday, and then ran out of ideas halfway through.

Looks good. Any thought of quatrefoils?

LikeLike

Thanks, Dave. What do you have in mind for the wood/resin chunks? Quatrefoils … hmmmm … maybe.

LikeLike

At the moment, I’m experimenting to see if I can make pretty double-dyed stabilized wood, but these are cut to size for making knife scales. A couple friends of mine are making beautiful knives and would be willing customers if I decide to start selling stabilized scales, especially if I can do so with woods native to MN.

https://www.instagram.com/vmknifeworks/

Beyond that, I’m looking at tools. I think that stabilized quarter-sawn white oak would be suitable for moulding plane bodies. If not, perhaps stabilized birch. Both of those are readily available here, while beech is very hard to find. But at some point I’d like to make my own set of moulding planes.

I’m also thinking about a wood-bodied smoothing plane. I’m not sure whether I’ll use stabilized wood or something hard like ipe for the sole, so I’ll probably build two and test-drive them for a while. I’ve also ordered a pair of shoulder plane kits from Ron Hock, and I’ll build one stock, and then build the second with stabilized wood and compare and contrast.

Finally, I built a miter-jack saw the other day (similar to your tenon saw), but assembled it with the saw plate in “the wrong way,” so I’ll be re-doing that. I was initially planning to use stabilized wood for the sole of that, but then I got a deal on a chunk of ipe at the lumber yard, and that’s working well for me. Haven’t figured out handle material yet…

So lots of potential uses, but nothing concrete yet. Still learning what I can do with it.

LikeLiked by 1 person

WOW! Sounding interesting. Good luck.

LikeLike

Thanks! Trying to make a lot of progress over the holidays, and I’ve gotten a lot done, but my to-do list somehow got longer. It’s almost going to be a relief to go back to work on Monday so I can relax a little. 😉

LikeLiked by 1 person

LOL! Go back to work and get some rest, Dave!

LikeLike